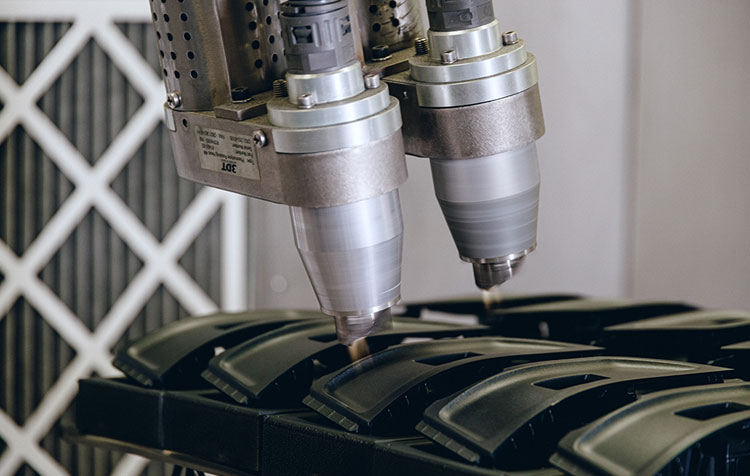

We are the experts in the application of multiple types of finishes. Our paint lines are fully automated in a multi-booth layout. All of our paint booths are equipped with water and six-axis robots, which allows us to quickly process a large number of parts per hour in a clean environment. We are able to paint parts with complicated geometries, and we are able to have total control of the paint thickness, paint gloss, and color of the paint being applied to your parts. In the end, our great fully automated paint lines offer you the highest quality parts at a competitive price.

Within the painting process, one of our main competitive advantages is in the preparation and cleaning of the pieces, which is carried out in four phases:

Manual cleaning

Mechanical aspiration

Ionized air cleaning

Plasma treatment

After the cleaning process, the pieces go to the painting booths, where we can apply up to four coatings without leaving the line. We do this through our very own “wet on wet” paint process.

The technology, digitization and experience in our painting systems allow us to have absolute control over the different factors of the process. We are able to achieve an exceptional finish, by automatically controlling the flow of paints, mixtures, temperature and humidity. Automating these controls limits the waste of materials and helps to achieve finished pieces on the first pass, while maintaining a quality product with the lowest scrap rate in the industry.

Our 4 booth systems can apply up to four coatings without leaving the line

Our staff is distinguished by their talent and experience. The title of “Paint Master” is not something that is acquired overnight, and it is a long road of providing quality solutions for our customers, such as our company being recognized by the Ford Motor Co. as a partner, who uses our processes and technology within their standard systems, also created by us.

Always at the forefront and in search of new trends, we have the ability to apply extremely complex paints that our customers require and our competition cannot understand. For example, we are industry leaders in applications that are high gloss, piano black, soft touch, silk gloss, and liquid chrome.